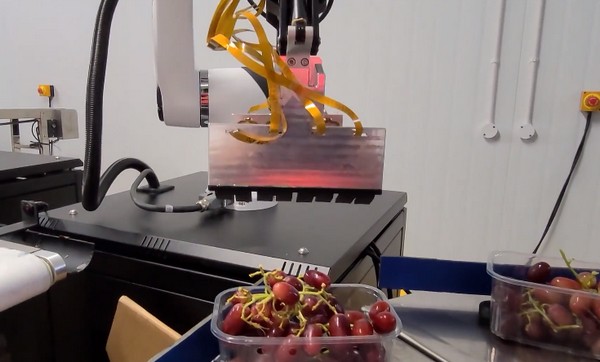

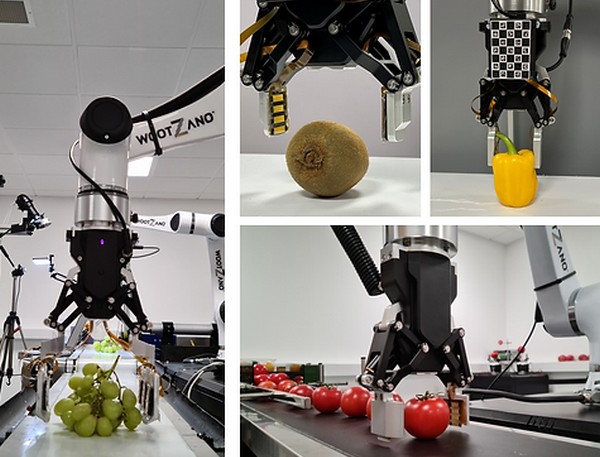

One robotics company based in England has a solution to reduce the amount of labour needed post-harvest. Wootzano makes dexterous robots that are able to delicately handle fresh produce using their patented electronic skin, proprietary hardware and machine learning algorithms in fully integrated robotic packaging systems.

Wootzano has created a state-of-the-art robotic solution for fruit and vegetable packaging lines.

“Our patented technology enables robots to have a greater sensory awareness of its environment, analysing data such as pressure, firmness, temperature, humidity and chemical signatures. To our knowledge our technology is unique, this level of highly intelligent, dexterous handling does not exist on post-harvest lines handling products such as grapes and tomatoes. It can not only replicate what a human would do but it can go beyond,” explains Dr Atif Syed Chairman, CEO and Founder of Wootzano.

“To handle products such as these the robot needs to know how much pressure needs to be applied, it also knows the direction of force. Almost everything about these robots is unique including the fact that they are affordable. We estimate that return on investment can be achieved within a year, this does of course depend on the usage.”

Wootzano have lines in operation just now and 1000’s of orders and are at full capacity in production, the autonomous packing lines are at work In British and European companies.

“The robots are designed for all fruit and vegetables, but at the moment they are mostly used for grapes and tomatoes this is because we are demand focussed and that is what our customers have asked for, but we are also getting a lot of requests for stone fruit, kiwis and avocado lines.

“Our system covers: quality control, weight estimation, trimming to size and picking and placing into punnet. We prepare the punnets to be sealed, but we do not seal them as part of our system. Different profiles can be programmed for different clients.

“The robot estimates the weight and can snip the bunch of grapes to make the correct weight. The different robots on the line can talk to each other to ensure the weight and also the presentation is right. There can also be person on the line to check the final presentation.

“In a couple of months we will be able to predict the potential shelf life of the product which will enable clients to put dynamic pricing in place. All of our robots are connected to a cloud network and all data captured is sent here. The robots are self-learning and self-adapting and they share knowledge and improve over time ”

After purchasing the robots clients sign up for a subscription fee, enabling updates, remote support and general maintenance.

The pre-set specifications for produce packing are likely to change in the future as the shift toward more sustainable packing methods and less waste. Because of the fast adoption of robotics, it's possible that specifications will alter to accommodate robots. However, this is a conversation which needs to be had.