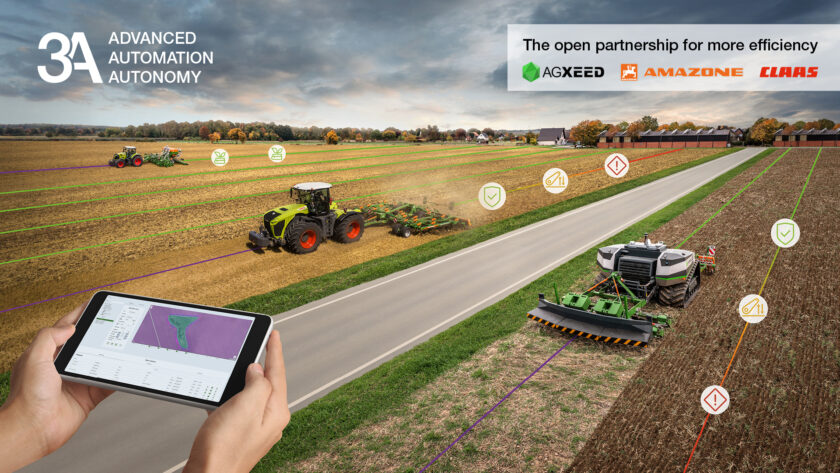

3a – Advanced Automation & Autonomy aims to accelerate the development, standardization and market introduction of partially and fully automated tractor-implement combinations , thanks to their integrated expertise and is open to other agricultural machinery manufacturers. The three partners have been collaborating in the field of autonomy for some time – Claas and Amazone are minority shareholders of the Dutch company AgXeed. With the establishment of 3A, companies will more closely integrate their individual areas of expertise and create further partnerships to enable faster and broader diffusion of the technologies developed.

Talks are also underway with other machine manufacturers interested in joining the multi-manufacturer group and thus playing an active role in expanding the range of applications

Innovative solutions for agricultural practices

The market-ready technology developed by 3A Group includes design and implementation software that was previously only available for field robots , but can now be used in conjunction with the AgXeed box to also control tractors and implements.

Depending on the requirements and available hardware , the level of control can range from highly automated to autonomous. From planning to implementation and analysis, technology eases the workload of agricultural managers and operators and increases the efficiency of agricultural processes.

Claas confirms the benefits of Shredlage®

Claas confirms the benefits of Shredlage®

The first products developed by 3A are Amazone AutoTill for mulch growers and Claas Autonomy connect, which includes the entire planning process.

In addition to AB lines and AB contours for automatic guidance and route optimization, orders for tractors today can include a prescription map. 3A goes one step further and enables pre-planning specifically designed for process optimization. This includes the start and end point of the work, headland turns and site-specific implement control. Advance planning with real machine parameters, for example or the rear linkage and hydraulic functions for adjusting the working depth and intensity, allows dynamic adjustments of the machine combination to be programmed before work, in order to achieve the desired quality.

Until now, closed systems included neither planning nor supervision of the tools and the subsequent execution process, with the exception of application rates. With Autonomy connect, however, Claas tractors in combination with implements can carry out work in the field with a high degree of automation , if not even completely autonomously . Depending on the degree of automation, the operator can carry out other tasks from the cab, or even in the field or on the farm. The tasks are planned in the Claas farm management information system (FMIS) or in the AgXeed portal, where it has long been possible to program routes and application maps.

So far, approaches to tillage automation have been limited to comfort functions. Autotill for Amazone growers continuously compares the soil tillage operating procedure with data from the tractors, carrying out supervision instead of the operator.

The new advantages

Claas Autonomy connect, Amazone AutoTill and AgXeed AgBot offer many significant advantages:

– Both the tractor and the implement perform all operations exactly as the farmer or contractor planned.

– The planning function not only calculates the best possible route, but also ensures that the tractor-implement combination is optimally configured . This avoids poor quality work and inefficiency resulting from incorrect settings.

– The first planning forms the basis for reducing the workload in subsequent years , as only seasonal adjustments are necessary, for example according to the main crop, the following crop and the rotation.

– Machine combination errors are detected by sensors and automatically corrected to maintain consistently high process quality. For example, the system automatically detects when the cultivator is at risk of clogging and adjusts the working depth and speed accordingly.

– The responsibility for producing optimal results no longer lies solely with the operator , who feels relieved of the pressure on himself, especially during long working days.

– Planned and process-optimized machine-plant combinations are more energy efficient and therefore more economical to operate.

– Highly skilled farmers and operators can carry out other more important operational tasks while the planned task is performed, since constant supervision is no longer needed. On non-autonomous tractors, the technology allows even the least skilled or experienced operators to produce optimal results.