And it is a huge market: it is estimated that the global agricultural equipment market will grow from $168.30 billion in 2022 to $272.36 billion by 2029. That equates to an impressive compound annual growth rate (CAGR) of 7.1%.

Farming machinery, being so specialized and often heavy-duty, is also very expensive. It is therefore imperative that maintenance and other factors ensure that machinery remains at optimal performance. This article will provide suggested solutions on how to ensure good machine performance in agriculture. Please note that the word ‘machinery’ here will encompass all mechanized farm equipment in general.

Have A System in Place

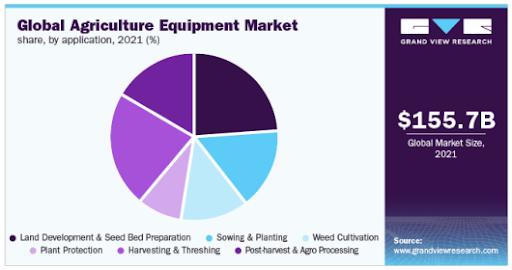

The sheer complexity, variety, and high cost of agricultural equipment demand the best possible management thereof. This variety can be seen in the graphic below, which provides insight into six leading categories of farm machinery as of 2021:

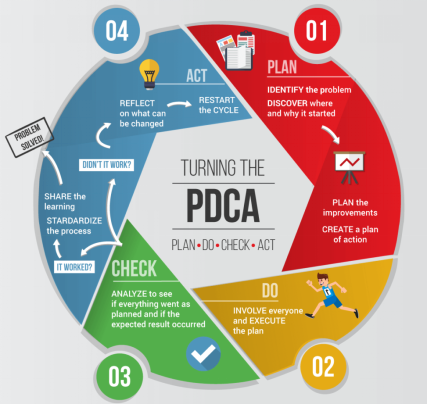

Plan-Do-Check-Act (PDCA) is the best management system template that is fit for any farm, regardless of its size. The PDCA Cycle is hardly new. It dates back to the 1920s and was popularised by Dr. W. Edwards Deming in the 1950s, which is why it is often referred to as the Deming Cycle. The simplicity of PDCA is its beauty and the reason why it continues to be the benchmark for management system theory and practice. Below is an instructive visual representation of each of the four steps or stages that comprise the Deming Cycle:

The importance of having a thorough management system cannot be overlooked. It enables the thorough identification and then planning for all farming machinery (the ‘Plan’), followed by implementation plans (the ‘Do’). Inspections and corrective actions (the ‘Check’) should then be undertaken at regular intervals to ensure the efficacy of the various objectives and targets, culminating in a review and possible improvements (the ‘Act’). Experts acknowledge how PDCA has made a difference to many agribusinesses in providing strategic and operational structure to farm management, including machinery.

Ensure A Proactive Maintenance Regime

Proactive maintenance trumps reactive maintenance even (or especially) in agriculture. The reason for that is simple: agriculture is a sector replete with very tight margins and a host of variables, such as inclement weather, often beyond the control of even the best farmers. As such, good machine performance relies on an appropriate, thorough scheduled maintenance regime.

The complexity and diverse range of agricultural machinery demand an appropriate and comprehensive maintenance schedule, which should include:

Adherence to manufacturer maintenance specifications

Corrective actions or replacement of defective components

Exterior inspections

Fluid irregularity checks

Interior inspections

Inventory parts maintenance

Oil changes

Planned maintenance of all machinery

Regular checks for warning signs of fatigue, stress, and corrosion in machinery

Systematic lubrications

Digitization of a maintenance system can be highly beneficial, allowing farming management not to get waylaid by overlooked maintenance or sudden machinery breakdowns. A computerized maintenance management system (CMMS) can be especially helpful by allowing a farm to plan and automate all maintenance-related tasks.

The result is an efficient, all-purpose maintenance system that both tracks and forecasts all maintenance, repair, and operations (MR) requirements.

The Importance of Lubrication

Lubrication could be considered the single most important factor in ensuring the optimal performance of farm machinery. An Australian magazine provided a stark example of just how important lubrication is — a harvester experiencing hydraulic fluid that is constantly shearing down will keep dropping its blades to the ground. The result will be excess harvesting of soil and debris, along with the grain or cane being harvested.

There are six primary functions of a machine or component lubricant:

Cleaning: by holding contaminants in suspension and not adhering to parts

Cooling: by transferring heat and ensuring machinery doesn’t overheat

Dampening and Cushioning: by relieving components from high stress

Lubrication: by providing a film or thin barrier between moving parts

Protection: by preventing oxidation and corrosion

Sealing: by filling in uneven surfaces or fissures in machinery

Different lubricants have different roles in ensuring the performance of farm machinery. According to Valvoline, there are three main types of lubricants used for agricultural machinery and applications. Engine oils protect the engine itself by preventing corrosion as a result of the accumulation of residues, grit, and dirt inside the engine.

They should also protect against high temperatures and constant pressure, such as those in gearboxes and engine valve trains. Gear and transmission oils and greases are the other two important categories of agricultural lubricants. The latter is typically essential for machinery that needs to withstand heavy loads, heavy shocks, water exposure, or harsh weather conditions.

Where possible, Go to Digital

Initial investments may be high, but going digital can result in significant cost savings for any farm operation, including ensuring that machinery is optimized. Technology is diverse and growing exponentially. Drones have become especially popular, even on smaller-scale farms.

In Kenya, for example, drones are used to perform aerial surveys of smallholder farms. The drones use DigiFarm, an integrated mobile platform. Drones allow farmers to be savvier on everything from the topography of the land to the best times to fertilize crops or spray their fields. This in turn ensures that machinery is used at optimal times and, therefore, less prone to unnecessary damage, wear and tear.

Geographic information system (GIS) mapping is also not only good for precision farming and sustainable crop yields but also for optimizing machinery performance. Allied to these exciting digital solutions is the growing role of 5G in agriculture and what it can achieve in terms of optimizing machinery usage. 5G has revolutionized the digital age because it is super fast (up to 100 times faster than 4G) and, therefore, has ultra-low latency.

These factors enable multiple simultaneous connections with 5G. The implications of 5G for farm machinery are immense: it means multiple machines on a farm can be interconnected, monitored, and controlled via sensors in the agricultural version of the Internet of Things (IoT).

These could be considered quite exciting times for agriculture. The world population continues to grow and the COVID-19 pandemic raised awareness of just how important local and regional agriculture is. Intelligent management and maintenance systems can be coupled with cutting-edge and fast-evolving digital solutions. The result should be optimized machinery performance, a boon for any farm.

Bryan Christiansen

Bryan Christiansen is the founder and CEO of Limble CMMS. Limble is a modern, easy-to-use mobile CMMS software that takes the stress and chaos out of maintenance by helping managers organize, automate, and streamline their maintenance operations.